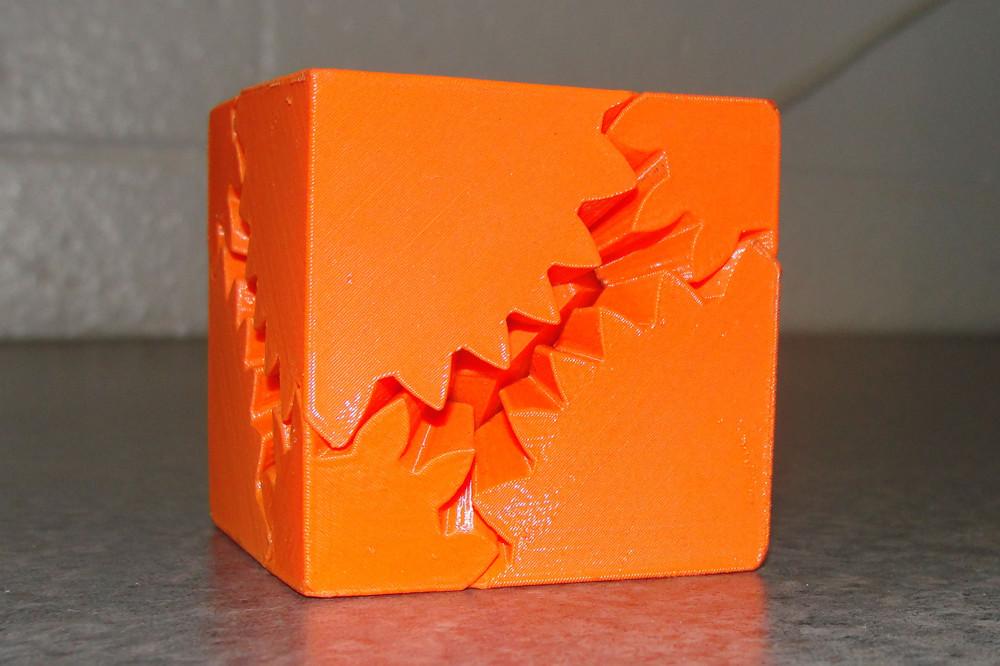

Rarely talked about in the hallways or classrooms is the new 3-dimensional printer in the Technology Department. The 3D printer has enabled the school to take a step toward technological innovation and advancement.

The funding for the printer came from students in Technology Club who sponsored a fundraiser to raise money to purchase the device. Currently 3D printer’s costs range from $600 to sophisticated ones that cost up to $2,000.

The printer is being used for various classes such as Intro to Engineering Design, Principles of Engineering, Civil Engineering, and most architectural classes. The printer allows for the manufacturing of simple items like cups, mugs, key chains, etc. The process allows for anything made of plastic to be manufactured in a matter of minutes.

Mr. Donald Whitman, a technology teacher, explained the impact of the printer on the school: “The really extraordinary thing about this printer is that all these cutting edge technologies and innovations are right here in our school for any student to use.”

In recent reports by USAToday and CNN a 3D printer, owned by a Californian-based medical research company, made a living liver (the smallest in the world) that survived for a record 40 hours without any malfunctions, signifying the capability of this equipment to not only affect the engineering and technological aspects, but also biological departments of teaching.

Whitman continued to comment that “it’s a really efficient tool for engineering especially.” The printer allows students with a passion in engineering and creating to implement their ideas, and turn them into actual life size objects.

The printer at NCHS, manufactures only plastic objects (some printers elsewhere have the capability of making objects out of wood, metal, steel etc.) Even though the printer makes objects out of plastic only, this capability allows one to design a prototype out of plastic and later design an actual functioning version using some other material if necessary like using a framework.

Whitman said that objects that students make out of the printer could “end up being a million dollar idea” which the student can manufacture and take to market. Expanding a student’s thinking abilities and imagination, this device also encourages student’s to take up tasks on their own and build objects using the principles the student has learned from the course.

Whitman stated that students have enjoyed learning about the printer and how it works – using a certain function called Autodesk that scans the model that one designs via a computer or laptop, and immediately generates a 3-dimensional prototype of it which is then made by the printer.

Another major benefit of this contraption is its ease of use, according to Whitman – “Anyone who has a general knowledge of designing and computer work can use it without a problem. And it does the rest of the work for you in just a few minutes.”

Now, after purchasing the 3-D printer, students of Tech Club are fundraising for a second printer by selling objects made out of the current one.

One of the added benefits of the printer is its ability to produce replacement parts for itself, avoiding added expense or repair cost.

![Community honors longtime coach Mr. Bryan Thomas before Oct. 3 game [photo gallery]](https://nchsinkspot.com/wp-content/uploads/2025/10/Thomas-6-1200x1200.jpg)

![Ironmen volleball head coach Ms. Christine Konopasek recorded her 400th career victory Oct. 21 as the Ironmen closed their regular season with a 2-0 sweep over Danville.

[Photo Illustration]](https://nchsinkspot.com/wp-content/uploads/2025/10/Vball400Thumb.png)

![Halloween candy cross section quiz [quiz]](https://nchsinkspot.com/wp-content/uploads/2022/10/Candy-cover-big-900x675.png)

![Average Jonah? [quiz]](https://nchsinkspot.com/wp-content/uploads/2022/05/average-jonah-900x600.png)

![[Photo Illustration]](https://nchsinkspot.com/wp-content/uploads/2025/09/trigger-words-1.png)

![Week 9: Coach Drengwitz on Week 8’s win, previewing Peoria High [video]](https://nchsinkspot.com/wp-content/uploads/2025/10/W9_PeoriaThumb.png)

![Postgame: Drengwitz on Community’s 56-6 win over Champaign Centennial; staying unbeaten in Big 12 [video]](https://nchsinkspot.com/wp-content/uploads/2025/10/10.17_FBwChampCent56-6_POST_thumb.png)

![Week 7: Coach Drengwitz recaps the Ironmen’s win over Bloomington, talks Danville [video]](https://nchsinkspot.com/wp-content/uploads/2025/10/Vikings-feature-Image-1200x675.png)

![On the Spot: This or That – Halloween [video]](https://nchsinkspot.com/wp-content/uploads/2024/10/tot-Halloween-YT-1200x675.png)

![On the Spot: This or That – Fall favorites [video]](https://nchsinkspot.com/wp-content/uploads/2024/10/ots-fall-web-1200x800.png)

![On the Spot – Teachers tested on 2023’s hottest words [video]](https://nchsinkspot.com/wp-content/uploads/2024/01/On-the-Spot-Teachers-tested-1200x675.png)